Internet of Things in Supply Chain Management

Imagine reducing your inventory errors to near zero and slashing delivery times by 30% – this is not a future dream but today’s reality with IoT in supply chain management. As an IoT developer at SumatoSoft, I’ve seen the power of IoT in transforming supply chains from traditional, reactive systems into dynamic, predictive networks. The secret? Leveraging the wealth of data provided by IoT devices to make smarter, faster decisions.

In this article, I’ll uncover the spectrum of IoT devices, from basic sensors to advanced analytics platforms, IoT advantages and challenges, and one more interesting topic.

As the final part, I’ll demonstrate to you the exact scenarios of how IoT transforms supply chain management across various industries. This section will be a deep dive into specific, practical examples illustrating the contrast between traditional methods and the innovative approaches enabled by IoT.

I implemented the Internet of Things in logistics, so I’ll do my best to speak from experience here.

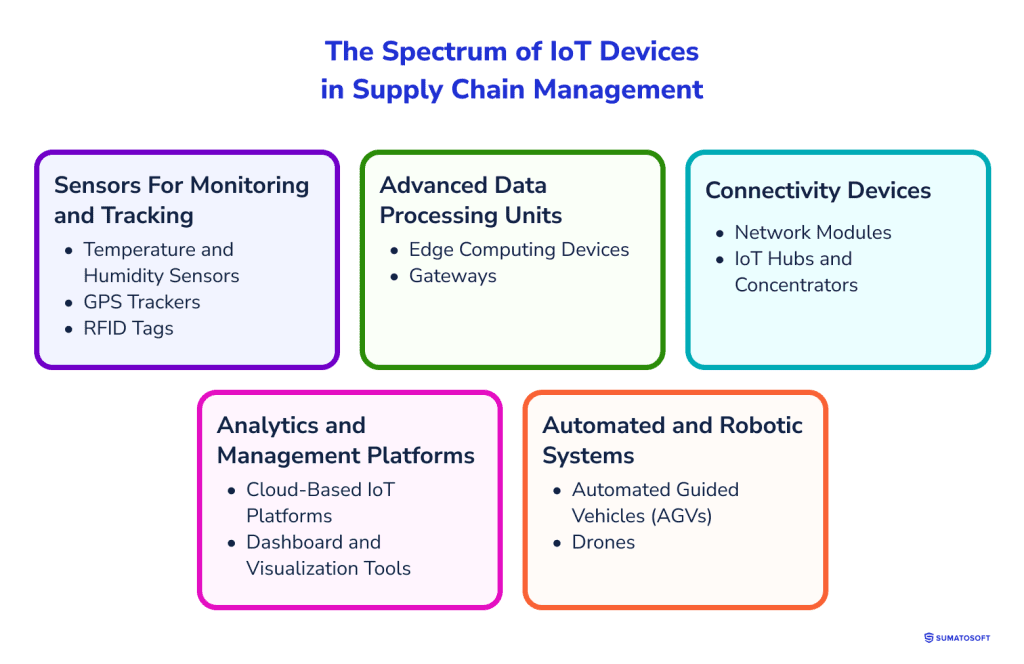

The Spectrum of IoT Devices in Supply Chain Management

In the realm of supply chain management, IoT devices range from the simplest sensors to the most sophisticated analytics platforms. Each plays a pivotal role in transforming traditional supply chain operations into more efficient, agile, and data-driven processes.

Some categories are simple to understand, and some, in turn, will demonstrate overlaps between one another. I will provide additional notes on categories that could lead to confusion.

Sensors For Monitoring and Tracking

Temperature and Humidity Sensors

Critical in industries like food, pharmaceuticals, and chemicals to ensure products are stored and transported within safe conditions.

GPS Trackers

Provide real-time location tracking of shipments, enhancing the visibility of goods in transit.

RFID Tags

Used for automated tracking of inventory, significantly reducing errors and time spent on manual counts.

Advanced Data Processing Units

The clarification note:

In the realm of IoT, there’s a notable overlap among various device categories, particularly when discussing edge computing, gateways, and IoT hubs/concentrators.

Edge computing refers to local data processing at or near the source of data generation, a capability that some modern gateways also possess. Gateways primarily act as intermediaries between IoT devices and the broader network, often with some data processing functions, aligning them with edge computing principles.

Meanwhile, IoT hubs and concentrators are more focused on aggregating and managing data flow and communication within IoT networks. Although these devices have distinct primary roles, advancements in technology have led to their functionalities increasingly intersecting, especially in the context of managing and processing data in IoT systems.

Edge Computing Devices

Edge computing refers to data processing that is performed at or near the source of data generation, rather than relying solely on a centralized data-processing warehouse. This concept is critical in IoT for reducing latency and bandwidth use. Within this category, several types of devices operate. Some of these devices can be classified as edge computing devices due to their data processing capabilities at or near the source. The list of devices is:

- uCPE (Universal customer premises equipment);

- industrial PCs;

- edge servers;

- micro data centers;

- edge gateways;

- edge notes;

- programmable automation controllers;

- smart routers and switchers.

Gateways

Gateways often serve as a bridge between IoT devices and the broader network. While they primarily aggregate and transmit data, many modern gateways also have built-in processing capabilities. This allows them to perform some level of edge computing, such as preliminary data analysis or filtering.

Connectivity devices

Network Modules

Enable communication between IoT devices and the central system using technologies like Wi-Fi, Bluetooth, and cellular networks.

IoT Hubs and Concentrators

These are more about centralizing data from various IoT devices and managing communication between these devices and the cloud or other network infrastructure. They can have some processing power but are often more focused on data aggregation and transmission. Specifically in the context of networks like LoRaWAN, I use concentrators that aggregate signals from multiple end-nodes. Other concentrator types are Sigfox, NB-IoT, and many many more.

Analytics and Management Platforms

Cloud-Based IoT Platforms

Offer powerful computing capabilities for data analysis, storage, and comprehensive supply chain management.

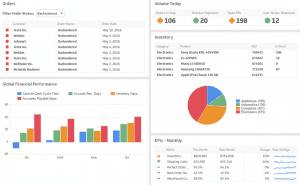

Dashboard and Visualization Tools

Interfaces for monitoring KPIs, trends, and generating actionable insights.

Automated and Robotic Systems

Automated Guided Vehicles (AGVs)

AGVs are primarily used for automating material handling and transport within a controlled environment like warehouses or manufacturing facilities. They directly contribute to the internal logistics of a warehouse, such as moving goods from one point to another, aiding in loading and unloading, and streamlining the movement of products within the facility.

Drones

Drones are flying machines that offer a surveillance opportunity, are useful for inventory management (e.g., in large warehouses or outdoor storage areas), and are being explored for direct delivery to customers, thus playing a role in both internal and external logistics.

Let’s move to the next part: some benefits businesses can count on when implementing the IoT in their operations.

Benefits Businesses Can Count on When Implementing IoT

The exact list of benefits depends on the role of the business in the supply chain. Raw material suppliers have the lowest levels of IoT implementation; manufacturers can improve operation efficiency and reduce downtimes; distributors get real-time data on the product location. We counted 11 positive effects of the IoT in logistics!

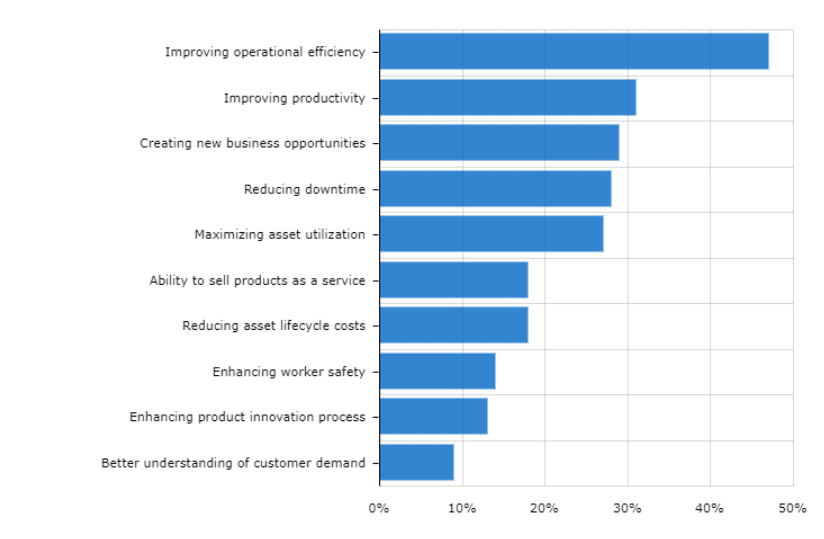

In general, according to the world industrial report from Morgan Stanley company, a global financial services firm, companies get the following benefits from implementing the Internet of Things:

And, speaking about benefits for different roles across and benefits of IoT in supply chain management, here is a breakdown:

| Role in Supply Chain | Benefits from IoT Implementation |

| Raw Material Supplier | – Improved monitoring of resource quality and quantity |

| Manufacturer | – Maximized production efficiency – Reduced downtime with predictive maintenance – Increased asset utilization by identifying bottlenecks and resource leaks – Integration of green strategies in resource consumption and environmental pollutions |

| Distributors | – Real-time tracking of product locations – Optimized delivery routes based on live data from carriers, airlines, border crossing stations, port authorities, meteorological satellites, and usual satellites – Improved handling of shipment delays and rerouting – Instant access to the content of any parcel using RFID tags – Live control of the environment in the transportation of perishable goods |

| Warehousing | – Accurate, real-time inventory tracking – Improved order-picking accuracy and efficiency with IoT-assisted systems – Constant monitoring of storage conditions with immediate alert system – Potential for full automation using AGVs |

| Retailer | – Streamlined loading and unloading processes using RFID tags – Shopping without scanners, lines, and checkouts – Accurate tracking and management of inventory |

In case you want to learn more, there is a good article that explains all these benefits in detail with real-life examples: IoT in supply chain. We also have the article “Impact of IoT on Businesses and Economy”. Meanwhile, we move on with challenges.

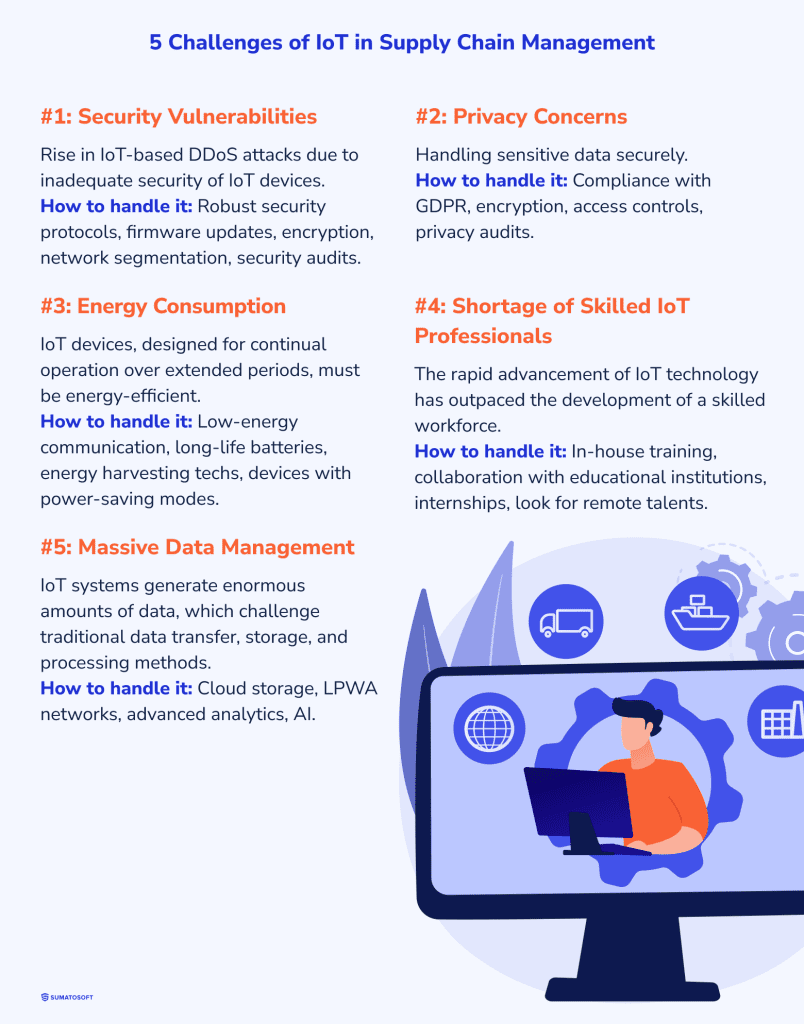

5 Challenges of IoT in Supply Chain Management

The integration of IoT in supply chain management, while impressive and promising, is not without its own set of challenges. The United States Freight and Logistics Market size only is estimated at USD 1.29 trillion in 2025, and is expected to reach USD 1.57 trillion by 2029. The stakes are high, so the following challenges must be addressed:

#1: Security Vulnerabilities of IoT Devices

With the increasing prevalence of IoT, there’s a corresponding rise in IoT-based DDoS attacks. This issue primarily stems from inadequate security measures in IoT devices, making them susceptible to misuse and exploitation.

How I Recommend to Handle It

When integrating IoT in supply chain management, Implement robust security protocols, regular firmware updates, and end-to-end encryption. Employ network segmentation to protect critical parts of the network. Conduct regular security audits and vulnerability assessments.

#2: Privacy Concerns

IoT devices often handle sensitive data, raising significant privacy concerns. Ensuring secure data transfer and preventing unauthorized external access are critical challenges that need addressing in IoT systems.

How I Recommend to Handle It

Ensure compliance with data protection regulations like GDPR. Use strong encryption for data transmission and storage. Implement strict access controls and regular privacy audits to prevent unauthorized data access.

#3: Energy Consumption

IoT devices, designed for continual operation over extended periods, pose energy consumption challenges, particularly in large-scale industrial IoT setups with thousands of little IoT devices. Managing energy efficiently in such extensive networks, where battery longevity is crucial, becomes a key operational concern.

How I Recommend to Handle It

Invest in low-energy communication technologies and long-life battery solutions right from the start when you decide to integrate IoT in supply chain management. Explore energy harvesting technologies and more efficient power management systems. Opt for devices with power-saving modes.

#4 Shortage of Skilled IoT Professionals

The rapid advancement of IoT technology has outpaced the development of a skilled workforce. There’s a noticeable gap in professionals skilled in building, maintaining, and analyzing IoT systems, attributable to the educational sector’s lag in adapting to these new technological demands.

How I Recommend to Handle It

Develop in-house training programs to upskill existing staff. Collaborate with educational institutions to shape relevant IoT courses. Foster internships and apprenticeships to nurture new talent. Embrace remote working to access a wider talent pool.

#5 Management of Massive Data Volumes

IoT systems generate enormous amounts of data, which challenge traditional data transfer, storage, and processing methods. Addressing this requires the adoption of technologies like LPWA (Low-Power Wide-Area) networks, NoSQL databases, and highly scalable cloud computing solutions.

How I Recommend to Handle It

Utilize cloud computing solutions for scalable data storage. Implement LPWA (Low-Power Wide-Area) networks for efficient data transmission. Leverage advanced data analytics and AI to process and extract meaningful insights from large datasets.

We are getting to the most valuable part – cases across different roles in IoT supply chain management.

IoT in Action: A Role-by-Role Breakdown in Supply Chain Transformation

I’ve observed firsthand how the integration of IoT technology is reshaping supply chain management. So, I want to take you through a series of narratives that vividly illustrate the transformative impact of IoT in supply chain management.

Each story will compare the traditional approach with the IoT-powered method, bringing to life the challenges and efficiencies at each stage. By sharing these stories, my aim is to provide you with a clearer, more tangible understanding of IoT’s impact – not just as a concept, but as a reality transforming the supply chain landscape. The list of roles is the same as I told about in the previous sections:

- raw material suppliers;

- manufacturers;

- distributors;

- warehousing;

- retailier.

Case #1: Raw Material Suppliers

Traditional Approach

In the traditional approach at the supplier stage of the supply chain management, imagine a day in the life of a raw material coordinator, John. His daily routine is heavily reliant on manual processes and reactive strategies.

John begins his day by updating and reviewing inventory levels in the company’s software system. While the system itself is digital, the data entry is manual, often leading to delays and inaccuracies.

Communication with manufacturers is predominantly via phone calls or emails. John often finds himself in situations where he can’t provide immediate updates on material availability or quality, as he’s waiting on information from the field or the warehouse.

Quality control is another area of constant challenge. John has to wait for reports from quality inspectors and has no real-time visibility into the conditions of the stored materials. Any issues discovered later in the supply chain can lead to significant disruptions and strained relationships with manufacturers.

The day ends with John feeling that he’s always a step behind, reacting to situations rather than proactively managing them.

IoT-Powered Approach

In the IoT-powered approach, meet Sarah, a supply chain manager at a raw material provider. Her day is vastly different from the traditional approach, thanks to IoT technology.

Sarah’s morning starts with her checking a digital dashboard that gives her real-time updates on inventory levels. IoT sensors in the warehouse provide accurate and current data, eliminating the need for manual counts and reducing errors significantly.

Communication with manufacturers is no longer a game of catch-up. Thanks to the IoT network, Sarah can provide them with instant updates on material availability, quality, and expected delivery times. This enhanced transparency strengthens relationships and builds trust.

Quality control is more streamlined and precise. IoT sensors monitor the condition of raw materials in real-time, alerting her immediately if any parameters deviate from the norm. This early detection prevents quality issues from escalating and ensures that only top-quality materials are sent to manufacturers.

Sarah ends her day with a sense of accomplishment. The IoT-powered approach has transformed her role from reactive problem-solving to strategic management. She’s not just keeping up; she’s anticipating and leading changes in the supply chain.

Case #2: Manufacturer

Traditional Approach

In the traditional approach for manufacturers, consider the daily routine of Emily, a production manager at a manufacturing plant.

Emily’s day involves overseeing the production line. However, the whole overseeing is based on periodic manual reports from the production floor. Adjustments to production rates are often delayed because every time a growth in demand occurs, Emily must collect and analyze manual reports from production, inventory, and procurement to adjust production rates.

Coordination with suppliers for raw materials is a juggling act. Emily frequently faces situations where she has to make do with what’s available, rather than what’s optimal, due to a lack of real-time communication and data from suppliers.

Equipment maintenance is conducted on a routine schedule, not based on actual usage or condition. This often leads to unexpected breakdowns, causing costly unplanned downtime.

Emily wants to implement sustainable practices in production to meet environmental standards. However, she is unable to optimize resource usage or reduce waste because she doesn’t know where to look for it.

As Emily concludes her day, she feels the constraints of her current system. She would like to optimize production efficiency but lacks timely data that would allow her to do so.

IoT-Powered Approach

In the IoT-enhanced manufacturing environment, Emily, the production manager, experiences a significantly different day.

Her morning starts with a glance at a tablet that provides real-time data from the production floor. IoT sensors on the equipment deliver instant updates on their performance and condition. This enables Emily to make immediate adjustments to production rates, aligning them with real-time demand and supply data.

Seamless coordination with suppliers is now a reality thanks to IoT-driven platforms from suppliers. Emily has up-to-the-minute information on raw material deliveries, quality, and quantities, allowing her to plan production schedules more effectively and reduce the risk of stockouts or excess inventory.

The predictive maintenance sensors detect early signs of wear or malfunction, allowing Emily to address issues before they lead to breakdowns, thereby reducing downtime and financial loss.

Emily is finally able to incorporate sustainable practices into the production process. Real-time data allows for precise control over resource use, minimizing waste and optimizing energy consumption.

At the end of her day, Emily feels empowered and in control. The proactive and data-driven environment fostered by IoT allows her to optimize production efficiency, respond swiftly to market demands, and maintain a high level of quality control.

Case #3: Warehouse

Traditional Approach

Meet Alex, a warehouse manager who relies on traditional methods to handle operations. His day is filled with challenges typical of a non-IoT-enhanced environment.

Each morning, Alex starts by checking the WMS which heavily relies on human input. This dependency often leads to time lags and potential inaccuracies in inventory tracking. This system’s lack of real-time updates makes it challenging for Alex to respond to inventory changes or efficiently manage stock levels swiftly.

Receiving and dispatching goods is a paperwork-heavy process, prone to delays and errors. Alex often finds discrepancies between what’s recorded and the actual stock, leading to confusion and inefficiency.

Throughout the day, Alex faces challenges in optimizing warehouse space and efficiently organizing goods. He has to strategically plan the placement of goods, balancing accessibility with space utilization, a process that is often slower and less effective compared to automated solutions.

Alex’s team uses handheld scanners and paper-based systems for order picking, a method that’s error-prone and inefficient. Mis-picks and misplaced items are common, leading to delays and customer dissatisfaction.

In cold storage areas, Alex and his team conduct periodic manual checks to monitor temperatures, ensuring goods are stored at optimal conditions. But these checks aren’t sufficient to promptly address fluctuations in storage conditions, potentially compromising the quality of goods.

At the end of the day, Alex often feels that despite his best efforts, the lack of technological support limits the warehouse’s efficiency.

IoT-Powered Approach

With the integration of IoT in supply chain management, Alex’s day now starts with an overview of a digital dashboard displaying real-time inventory levels, thanks to IoT sensors and RFID technology. This system ensures accurate, up-to-date information, enabling better inventory management and decision-making.

Automated receiving and dispatching systems streamline processes, reduce paperwork, and minimize errors. Real-time tracking of goods ensures that inventory records are always accurate, significantly reducing discrepancies.

Warehouse space optimization is now handled by intelligent software that analyzes data from IoT devices, enabling more efficient organization and storage of goods. Temperature sensors continuously monitor the conditions, sending real-time alerts if temperatures deviate from the set parameters.

IoT-enhanced picking systems, including smart glasses and automated guided vehicles (AGVs), have replaced manual picking methods. This technology not only speeds up the process but also significantly reduces errors, improving overall customer satisfaction.

A sense of achievement now marks the end of Alex’s day. The IoT-powered warehouse is more efficient, agile, and responsive to the needs of the supply chain, and Alex feels empowered with the tools and data to make informed decisions.

Case #4: Distributor / Logistics Provider

Traditional Approach

Consider the daily routine of Tom, a logistics coordinator working in a traditional distribution setting.

Tom starts his day with a manual review of shipping schedules and tracking shipments through phone calls or basic online systems with manual shipping status updates. It’s slow, but Tom got used to it.

Tom frequently deals with customer inquiries about shipment statuses, but without real-time data, he’s unable to provide immediate and accurate updates, impacting customer satisfaction.

Handling emergencies or unexpected delays, like traffic or weather disruptions, is a challenge. Tom often learns about these issues too late which makes it hard to reroute or adjust plans quickly.

Route planning for shipments is done using simple mapping software without real-time traffic or weather data. This often results in suboptimal routing, leading to delays and increased fuel costs.

Environmental monitoring for perishable goods during transit typically involves manual checks at predetermined intervals. Occasionally, drivers may notice unsuitable storage conditions too late, leading to disputes with Clients and the potential return of compromised goods.At the end of the day, Tom often feels overwhelmed due to his inability to optimize logistics operations and manual routine tasks.

IoT-Powered Approach

Consider the day of Evelyn. With IoT technology integrated into the logistics operations, Evelyn’s day begins by looking at the mapping software with the real-time locations and statuses of all shipments.

Whenever a customer contacts Evelyn, she can tell the status of any shipment immediately. This transparency greatly improves customer satisfaction and trust.

Advanced route optimization software, using real-time data like traffic patterns and weather forecasts, automatically adjusts shipment routes. This ensures more timely deliveries and optimized routes that reduce fuel costs. Moreover, the IoT system provides early warnings and alternative route options, allowing Tom to reroute shipments swiftly to avoid disruptions.

Smart sensors installed within transportation vehicles continuously track conditions like temperature, humidity, and even air quality in real-time. They alert Tom immediately if any storage conditionals fall outside the preset safe parameters. At the end of the day, Evelyn feels more in control and effective in his role. The IoT-powered approach gives her real-time data on any transportation unit in the fleet.

Case #5: Retail

Traditional Approach

Meet Lisa, a retail store manager who relies on manual and less-technology methods to manage her store operations.

Lisa starts her day by manually checking inventory levels and relying on periodic stock reports to determine restocking needs. This often leads to either overstocking or stockouts, as the data is not real-time.

During unloading, Liza’s team must manually check the contents of each parcel. It’s a prevalent but still time-consuming process that takes several hours during her day.

Checkout processes are traditional, with cashiers manually scanning items and handling payments. This often results in long queues during peak hours, affecting the customer shopping experience.

Security and loss prevention are constant concerns, with Lisa relying on basic surveillance cameras and security personnel to address shoplifting or inventory discrepancies.At the end of the day, Lisa often feels helpless due to her inability to address the challenges in front of her.

IoT-Powered Approach

With the adoption of IoT, Lisa’s role as a retail store manager is significantly more dynamic and efficient.

Her day begins with an overview of a digital inventory management system, powered by IoT sensors and RFID tags. This provides real-time data on stock levels, enabling precise and timely restocking decisions.

Goods unloading processes are streamlined as each parcel is tagged with RFID chips. Automatic content verification is now a reality, which drastically reduces the time and effort for loading and unloading.

Automated checkout systems, such as smart carts or RFID-based checkout, streamline the purchasing process, virtually eliminating long wait times and improving the overall shopping experience.

An advanced security system, using smart surveillance cameras and RFID tags to track items within the store, provides real-time alerts on potential thefts or inventory issues, significantly improving loss prevention measures.At the end of her day, Lisa feels more satisfied and in control, observing happy customers easily buying staff and accurate inventory levels.

SumatoSoft Brings IoT In Supply Chain Management

SumatoSoft has been building IoT solutions since 2012, delivering custom enterprise software and developing MVPs to startups gain a competitive advantage and improve their efficiency, effectiveness, and profit through business digitalization.

SumatoSoft offers industry-focused IoT solutions for supply chain, healthcare, retail, manufacturing, smart homes & cities, and automotive domains. Examples include a smart fridge sensors system, fitness tracking system, warehouse automation, fleet management, robotics, smart traffic lights, and more.

Every solution SumatoSoft builds comes with excellent security and scalability for future changes in terms of new features, fleet expansion, new users, and increased workload.

SumatoSoft IoT services include:

- all-around IoT applications;

- connectivity management;

- device management;

- data visualization;

- IoT data analytics;

- IoT consulting.

SumatoSoft succeeded in building a more manageable solution that is much easier to maintain.

Although they are a small team, their project management reflects the excellence of a larger company. Their team delivers high-quality results, attentive service, and reasonable pricing.

The SumatoSoft team has built 250 custom software solutions for 27 countries for 11 industries. After more than 12 years on the market, the company became a reliable technical partner to its Clients, demonstrating a 98% Client satisfaction rate with the quality of services they provide.

Contact us to get a free quote for your project.

The IoT Journey Continues

The integration of IoT in supply chain management represents a paradigm shift across the whole role of the supply chain. From raw material suppliers to warehouse managers, IoT transforms traditional processes into dynamic, efficient, and data-driven operations. It’s not merely a technological upgrade but a comprehensive re-envisioning of supply chain workflows.

This shift towards IoT-enabled supply chains is essential for meeting the demands of a rapidly evolving global market. That’s why I will continue developing my skills in the IoT and implementing it in the Client’s business.

Let’s start

If you have any questions, email us info@sumatosoft.com